MATEC 30LD - MODULAR series

3-axis double-spindle machining centre with long bed

Two work areas. Loading and unloading during machining

Reduction of the piece time by 50%

Tool change directly above the workpiece

Work area change in approx. 4 seconds

Ideal concept for manual and automatic loading

With two spindles – to reduce the unit cost

The MATEC 30LD belongs to the MODULAR SERIES.

The proven design principles of the MATEC modular

system guarantee the ideal configuration for almost any

production methods. Customer requirements and

machining centre can thus be optimally matched.

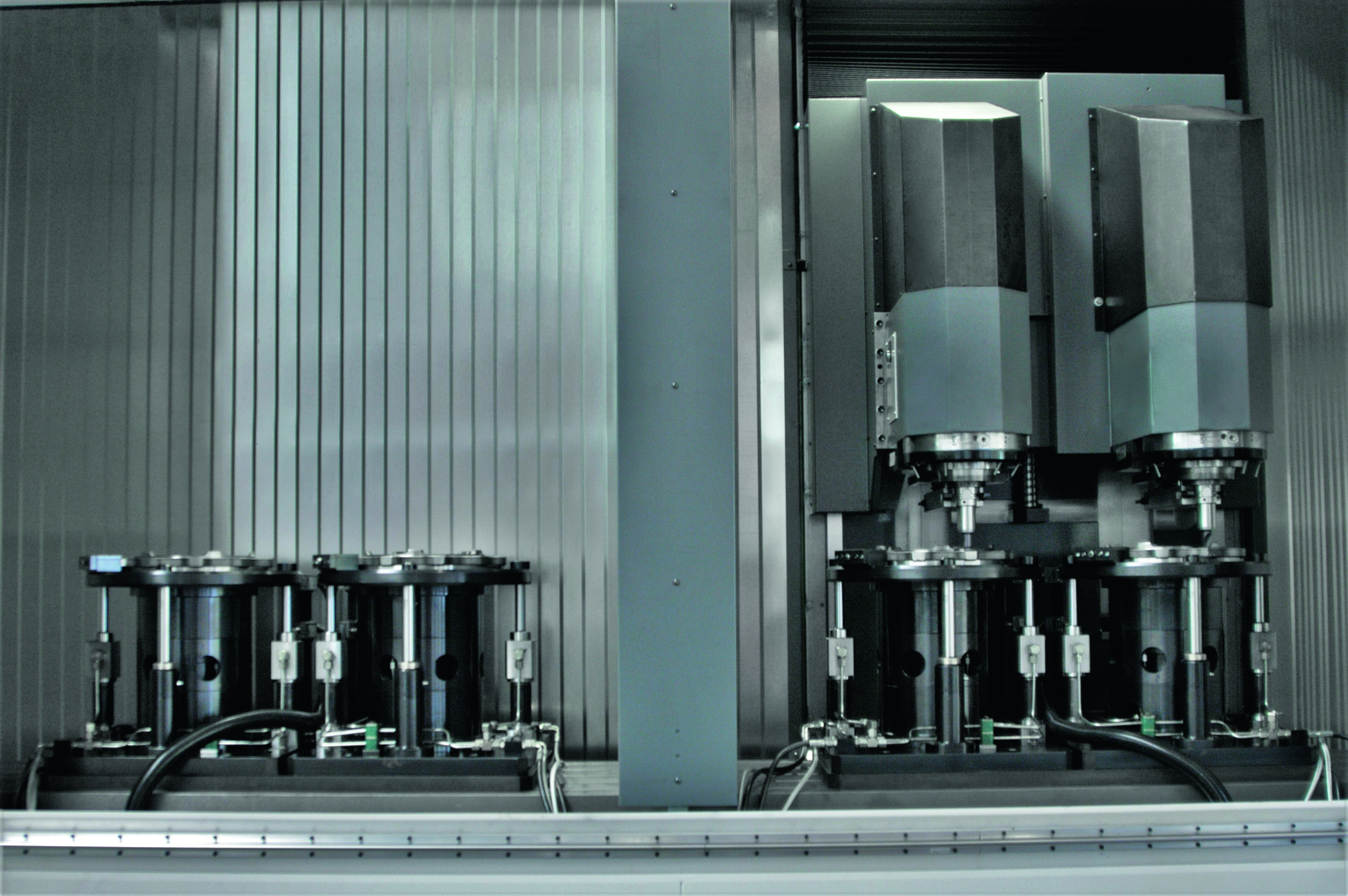

The basic machine with double spindle and two work

areas has already been designed for series production.

Furthermore, it can be expanded by various optional

equipment.

Variants of the basic machine

- Motor spindles, increased power and speed.

- Extension of the spindle distance from 400 to 550 mm.

- Second Z-axis for compensation of different workpiece lengths.

Variants of the machine table assembly group

- Standard fixed table, optionally with table lowering by 100 mm.

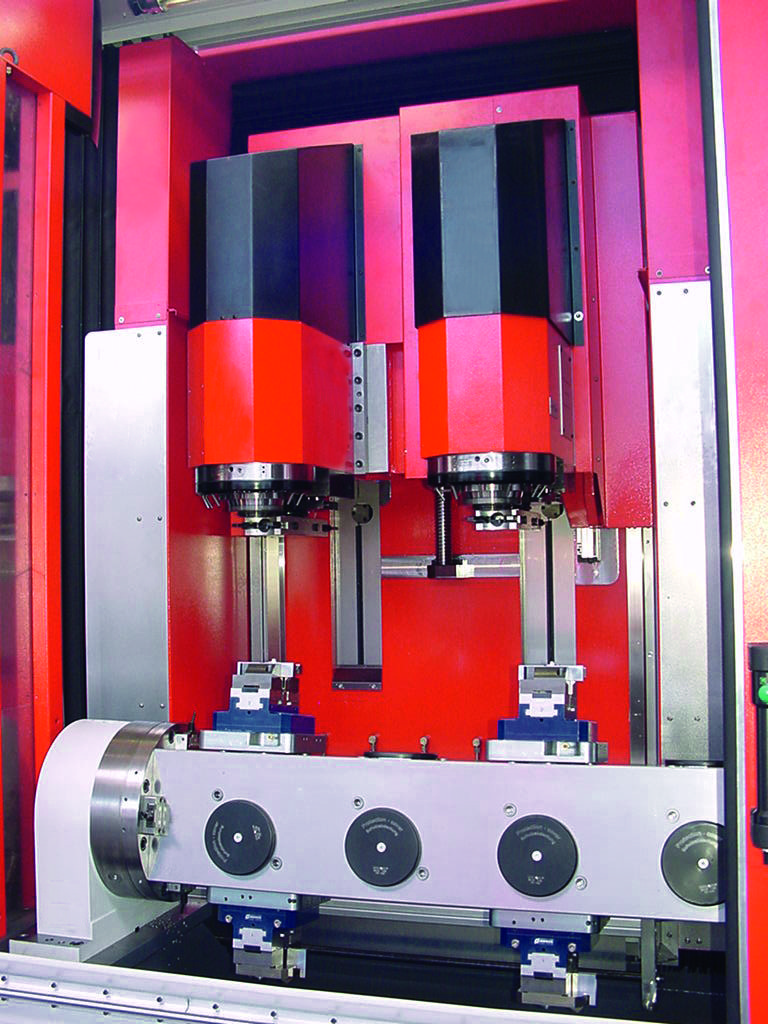

- Prepared for 1-axis or 2-axis double rotary tables for multi-sided machining.

- Version without fixed table, however, with mounting brackets for the installation of various equipment.

- Swivelling machine table in bridge design

Pendulum machining with two work areas. Version without fi xed table,

however, with mounting brackets for the installation of various equipment for high workpieces

Rotary table – swivel bridge – counter bearing:

Clamping capacity for 16 workpieces