Gantry Machines

Gantry machines, which touch engineers' hearts

Excellent large part production

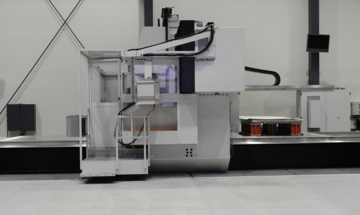

The design of the gantry machines is focused on achieving a small

footprint, high stability and the maximum possible performance.

One of the most important elements for stability and precision is the

special design of the gantry beam with its disproportionately large

cross-section. The unique stiffness of the machine ensures maximum

contour fidelity and surface quality on the workpiece. 3D molds, large-

scale and high-volume parts can be machined with appropriate process

optimization so as to save both time and money. The applications of

these extraordinary gantries is not only tool and mold making, but also

large-scale production. For all types of materials, a multitude of main

spindles with appropriate power and speed is available.

For specific applications e.g. machining in the interior of housings,

different replaceable heads are available. Extended milling spindles,

special angular heads or multi-spindle heads can be loaded automatically

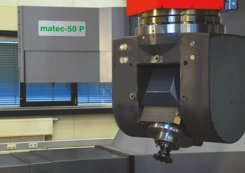

during production on a pick-up stations. The MATEC portal series is

offered in two performance classes and two types. According to the

performance requirements, tool systems with SK40|HSK-A 63 or

SK50|HSK-A 100 are available. As a design, on the one hand, the

ergonomic table version for the machine operator and, on the other hand,

for the large part production, a floor-running version with a machine table

on the floor level is offered.