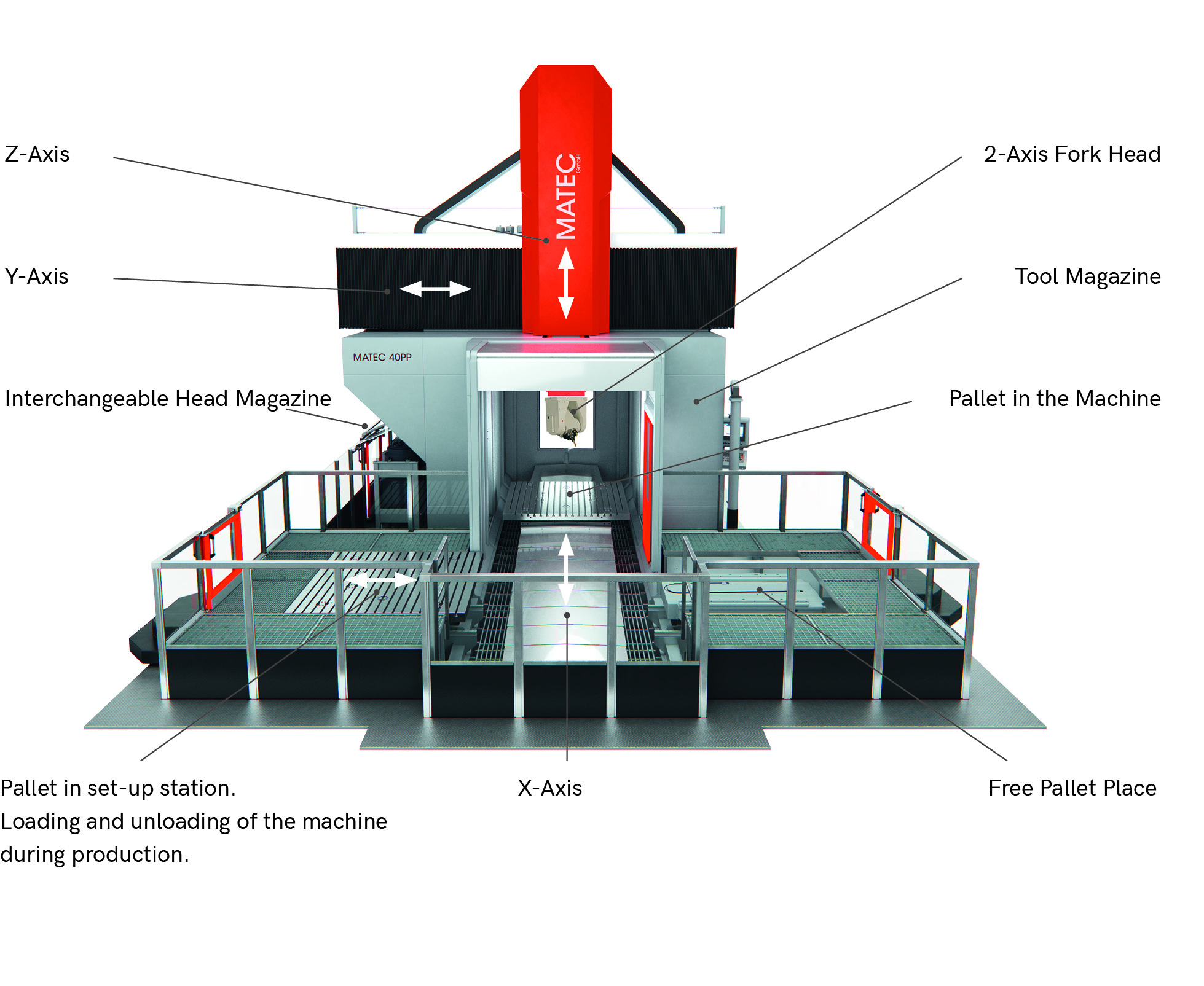

MATEC 30PP | 40PP - Stationary gantry | Moving table with pallet change

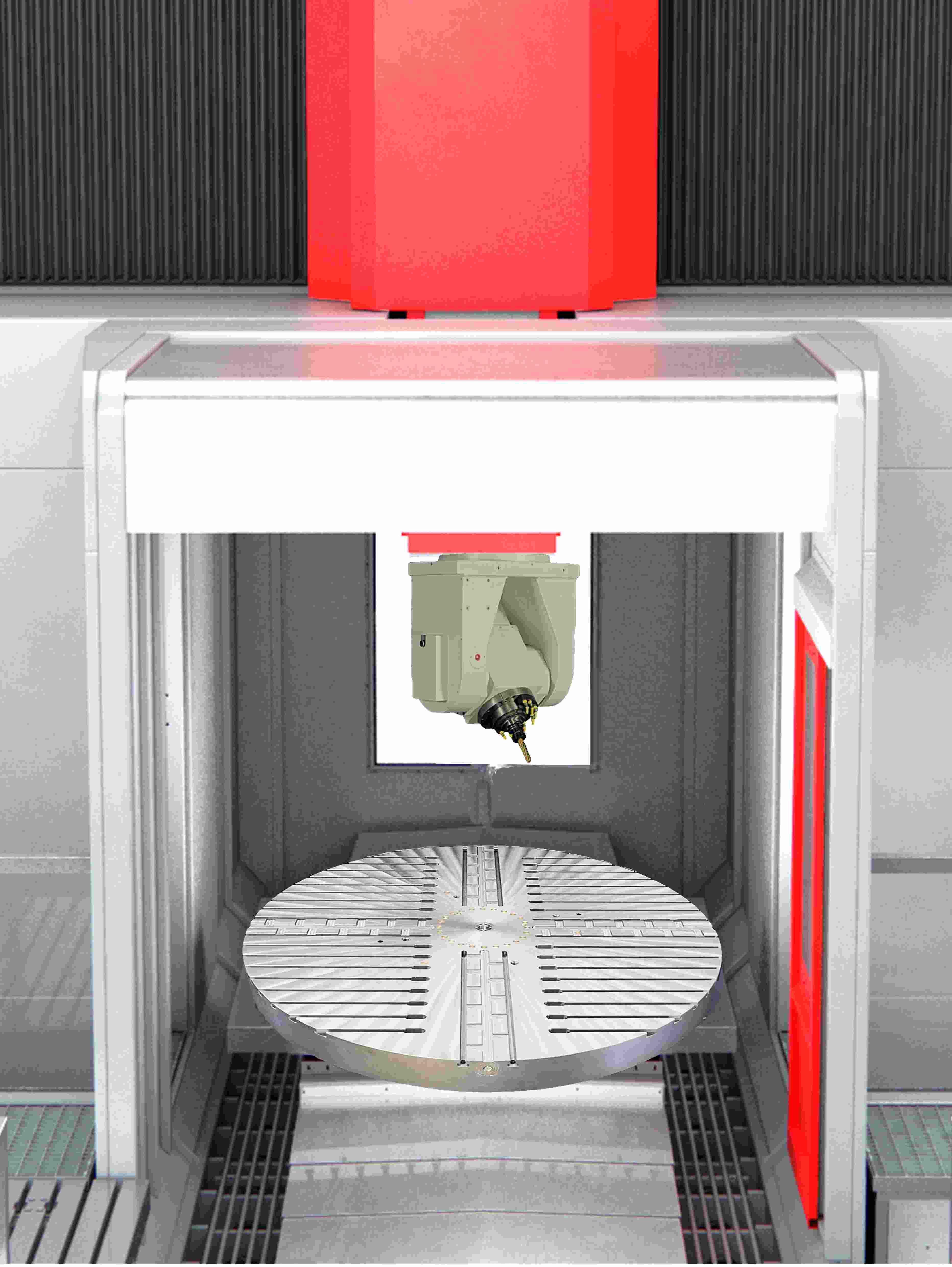

5-Axis Gantry Series | 2-Axis Fork Head

Performance Class HSK63 | HSK100

CNC Control Unit: SIEMENS | HEIDENHAIN

The pallet changer is the core element of the MATEC PP series. Setting up or reclamping while the machine is in production, results in extremely high time savings, especially for large parts. In addition to all the other advantages of the machine, this results in a convincing cost-effectiveness. With an optional two additional pallet stations and a corresponding running time of the workpieces, it is possible to produce in a multi-shift production with a considerably reduced workforce.

If needed, the automatic head change and the available capacity of tool places make the machine extremely flexible. State-of-the-art monitoring systems ensure safe production.

| Work area | |

| X-axis | 3,750 | 4,750 | 5,750 | 6,750 mm |

| Y-axis | 3,400 | 4,400 mm |

| Z-axis | 1,500 | 1,800 | 2,100 mm |

| Clearance height | 1,350 | 1,650 | 2,050 mm |

| Clearance width | 2,320 | 3,320 mm |

| Main spindle | |

| Speed | 10,000 | 15,000 | 24,000 1/min |

| Power max. | 96 kW |

| Torque max. | 690 Nm |

| Tool magazine | |

| Tool places | 40 | 48 | max. 680 pcs. |

| Tool length | 450 mm |

| Tool weight | 20 kg |

Interchangeable head magazine (option)

Ready to take 4 different machining heads.

Automatic change procedure.

|

|

| 2-Axis fork head | |

| Swivel radius | 250 mm |

| Rotation angle C-axis | ± 180° |

| Direct measuring system | ± 6" |

| Rotation angle A-axis | ± 105° |

| Direct measuring system | ± 5" |

| Clamping table (pallet) | |

| Pallet length | 2,000 – 5,000 mm |

| Pallet width | 2,000 – 3,000 mm |

| Pallet load | 4,000 kg |

| (depending on table size and drive system) | |

| Axis drive with ball screw | |

| Feed | rapid traverse | 30 m/min |

| Option: X-axis with linear drive or toothed rack drive. | |