Pallet automation - Our modular series – with intelligent automation

Performance class HSK63 | HSK100

Maximum flexibility with workpiece and pallet change

Specification

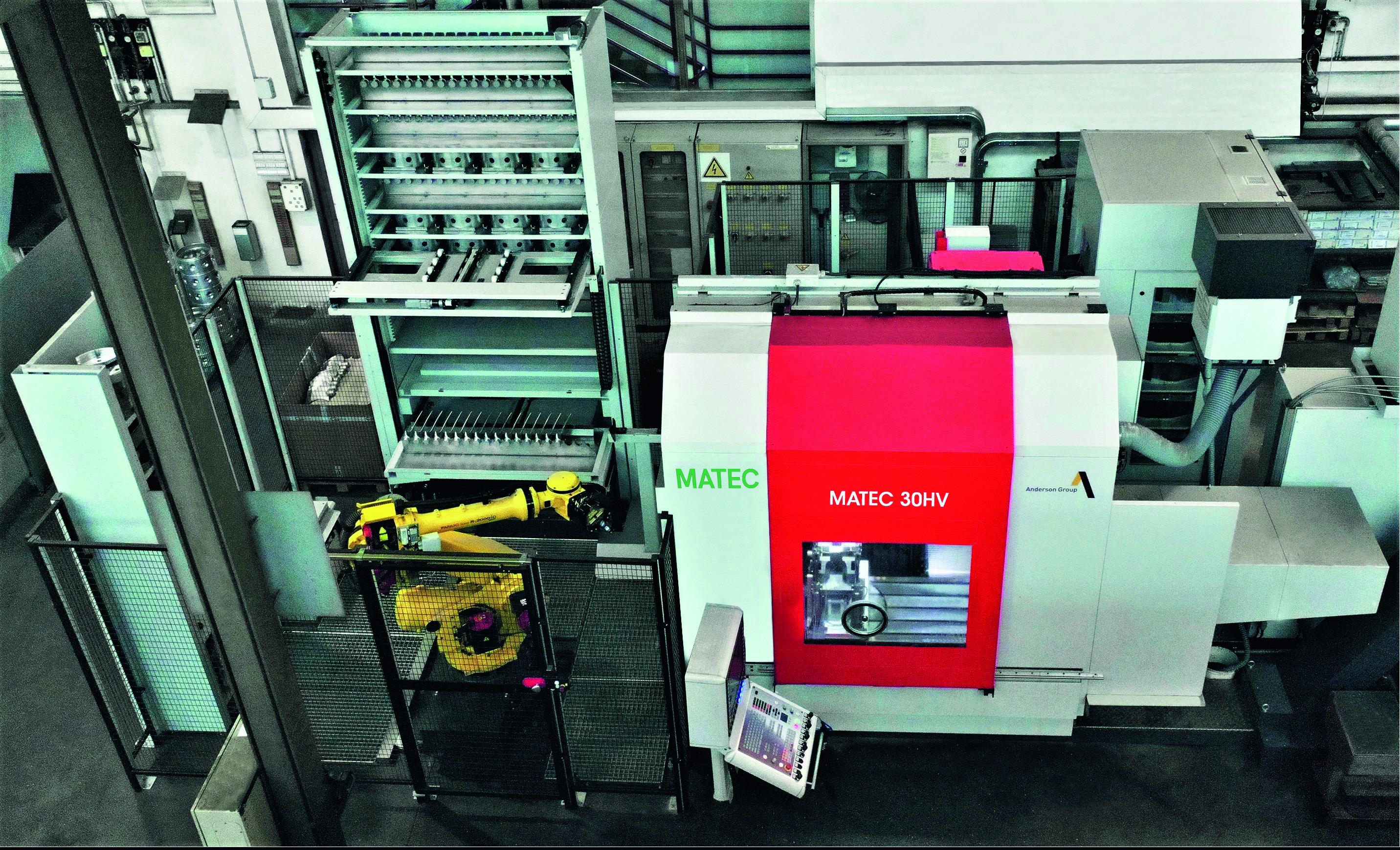

MATEC 30HV

- Tool capacity 48 or 268 tools with add-on magazine

- Fully enclosed work area, prepared for mist collection

- 6-axis robot, size based on the required payload or workpiece weight

- High rack with workpiece drawers, individually adjustable to the specific workpiece height

- Alignment stations for different workpieces

Pallet changer with round storage unit

(example: customized solution)

- Space-saving round pallet storage unit with 24 storage places on two levels

- Pallet size 320 x 320 mm

- MATEC 30HV machining centre with swivel head

- CNC rotary table with Ø 800 mm and turning function (e.g. 800 1/min.)

- 5-sided machining with a total of 268 tool places

- Rotary table with fixture quick-change system

- Rotary distributor for media transfer

- Automation module

High flexibility

A zero-point clamping system is used a the basic pallet

clamping system on the rotary table. Set-up changes

from automated to manual production are realized in no

time. The entire work area is thus available

Basic fixture for automation on the rotary table. Workpiece pallet clamping via zero-point clamping system.

Pallet sizes ranging from 150 x 150 mm to 800 x 800 mm; Round pallet storage unit with pallet handling function

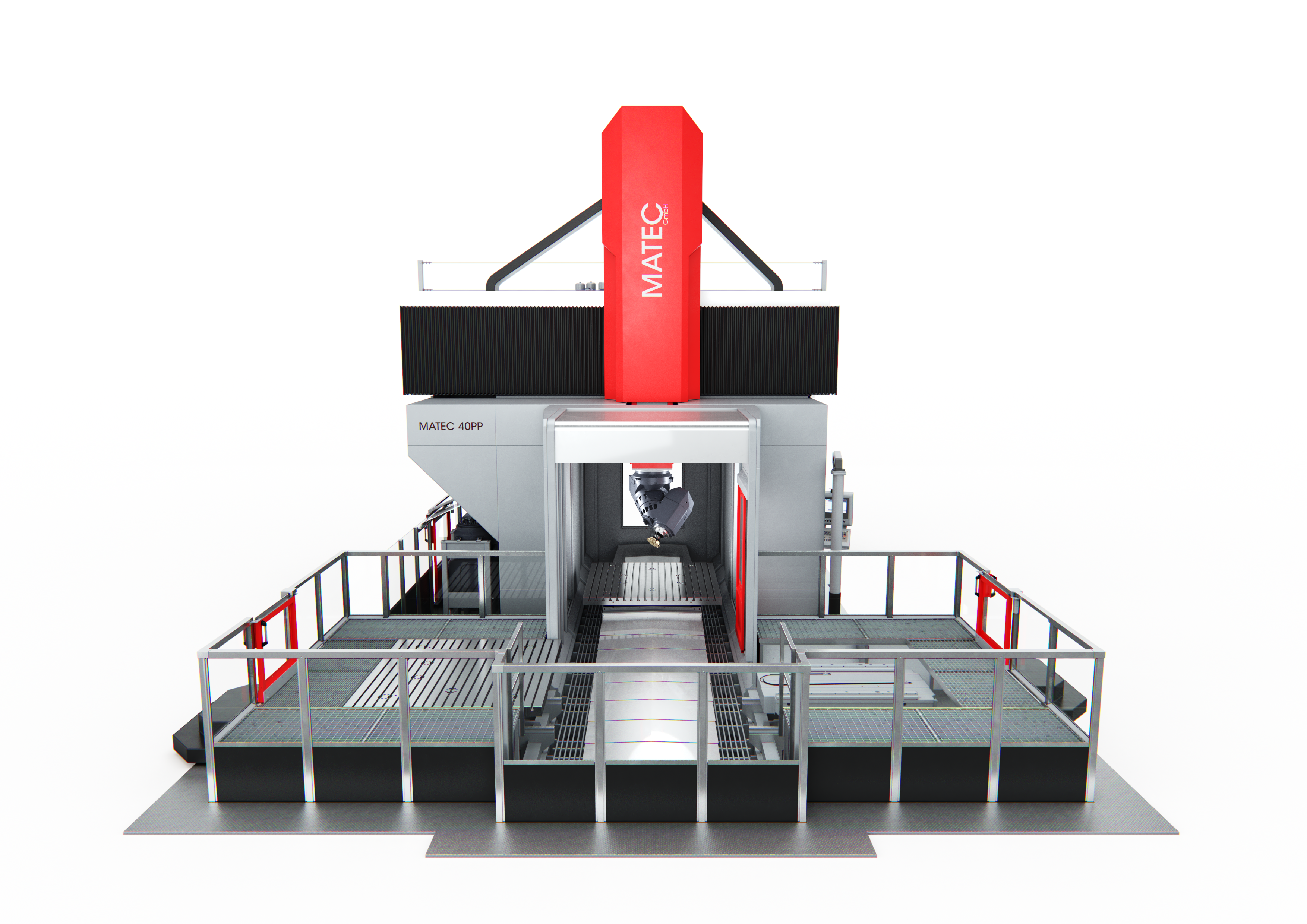

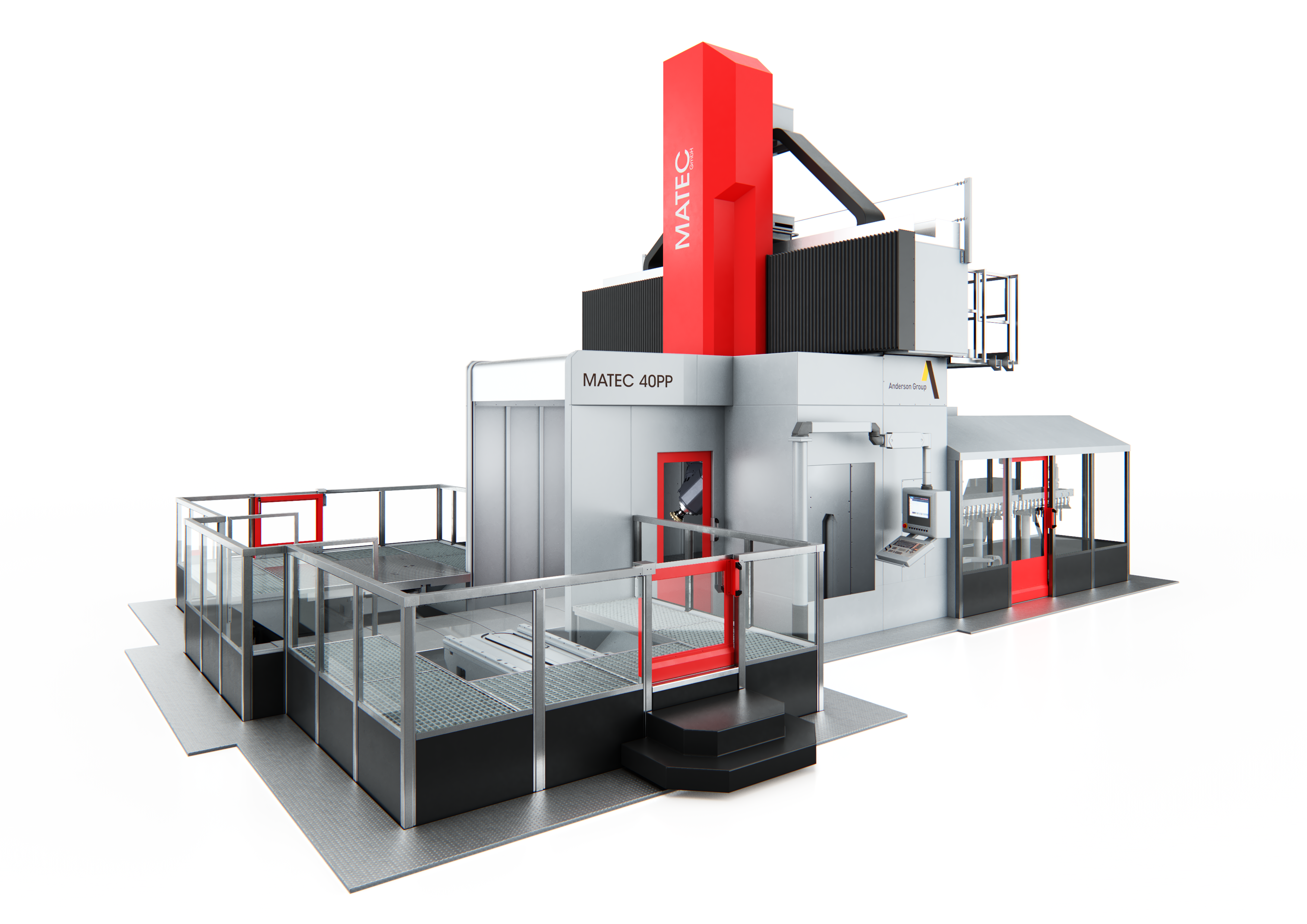

Gantry centres MATEC 30PP | 40PP

5-axis gantry series

Stationary gantry | Moving table

up to 5 replaceable heads (more heads on request)

X-axis: up to 7,000 mm

Y-axis: up to 4,800 mm

Z-axis: up to 2,100 mm

- Pallet size 2,000 x 2,000 to 6,000 x 3,000 mm,

corresponds to the workpiece size, for a tool length of 250 mm - 2-axis universal head (infinitely variable), optional with 2-axis fork head

- Speeds up to 30,000 1/min

- Motor spindle up to 159 kW

- Torque up to 690 Nm

- Axis drives with ball screw, optional rack and pinion drive or linear drive

- Tool capacity 40 bis 680 places or tool handling with robot for up to 250 tools

- Pallet changer for 2 to 4 pallets

- Workpiece weight 1 t/m2, optionally higher payload

- Fully enclosed work area, prepared for mist collection

- Manual pallet exchange

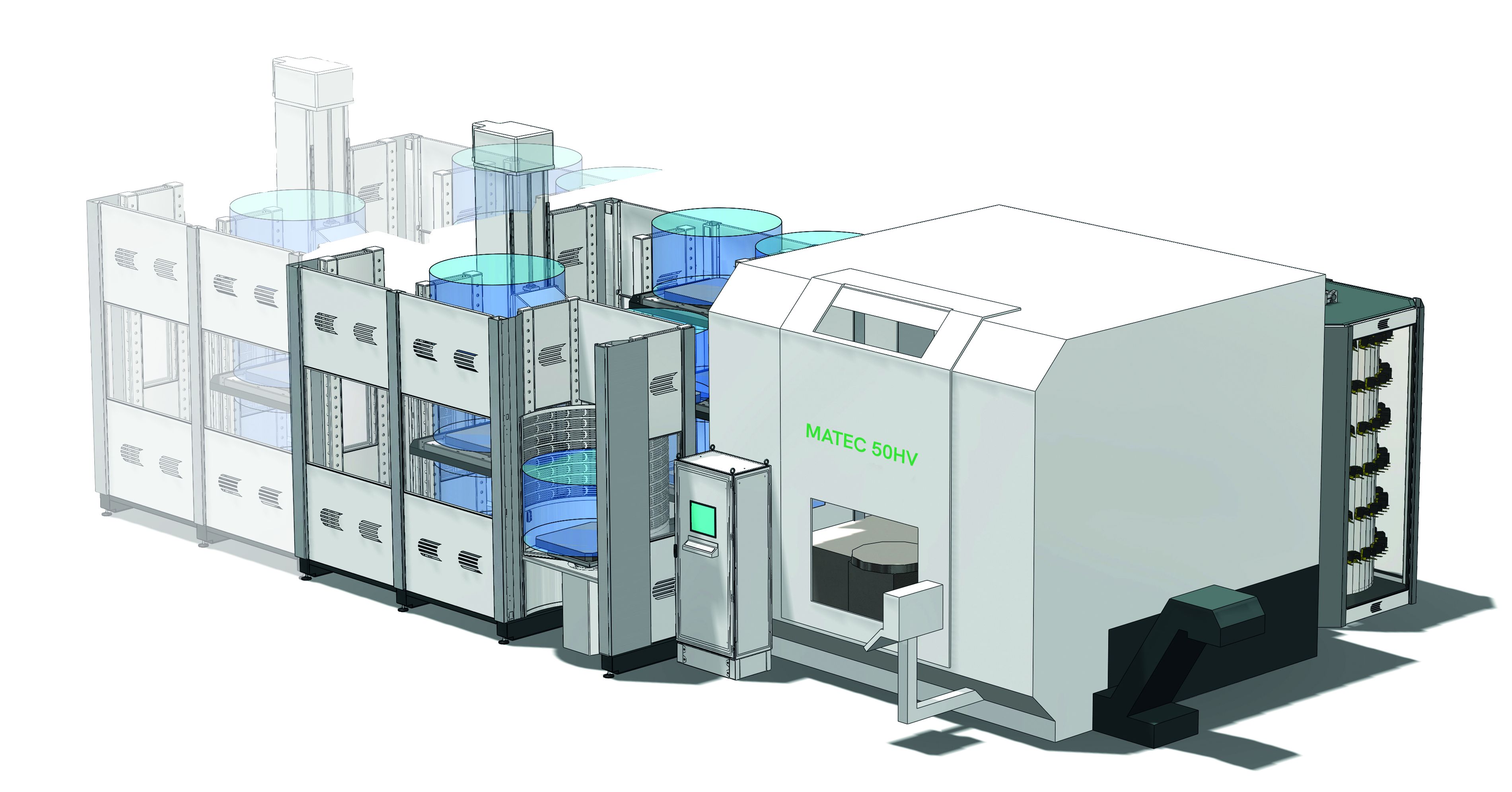

Pallet automation (customer solution)

- Pallet size 1,000 x 1,000 mm

- Pallet storage unit with 9 places (modular expansion available)

- Expandable to a pallet pool with further places

- Workpiece size L x B x H 1,000 x 1,000 x 1,000 mm

- Max. pallet load 1,500 kg

- Rotatable loading and unloading station

- Manual workpiece clamping

MATEC 50HV machining centre

X-axis 2,000 mm

Y-axis 1,125 mm

Z-axis 1,300 mm

- Tool holder HSK100

- Motor spindle 12,000 1/min

- Drive power 96 kW

- Torque 521 Nm

- 480 tool places

- CNC rotary table Ø 1,000 mm

- Transport load 5,500 kg

Schematic diagrams – MATEC 30PP with pallet changer