Workpiece automation - High-flexibility automation solutions

Performance class HSK63 | HSK100

Automation solution that combines minimum footprint with maximum storage capacity

Optimum adaptation to the available floor space for production

Simple operation

High flexibility

Small footprint

Specifications

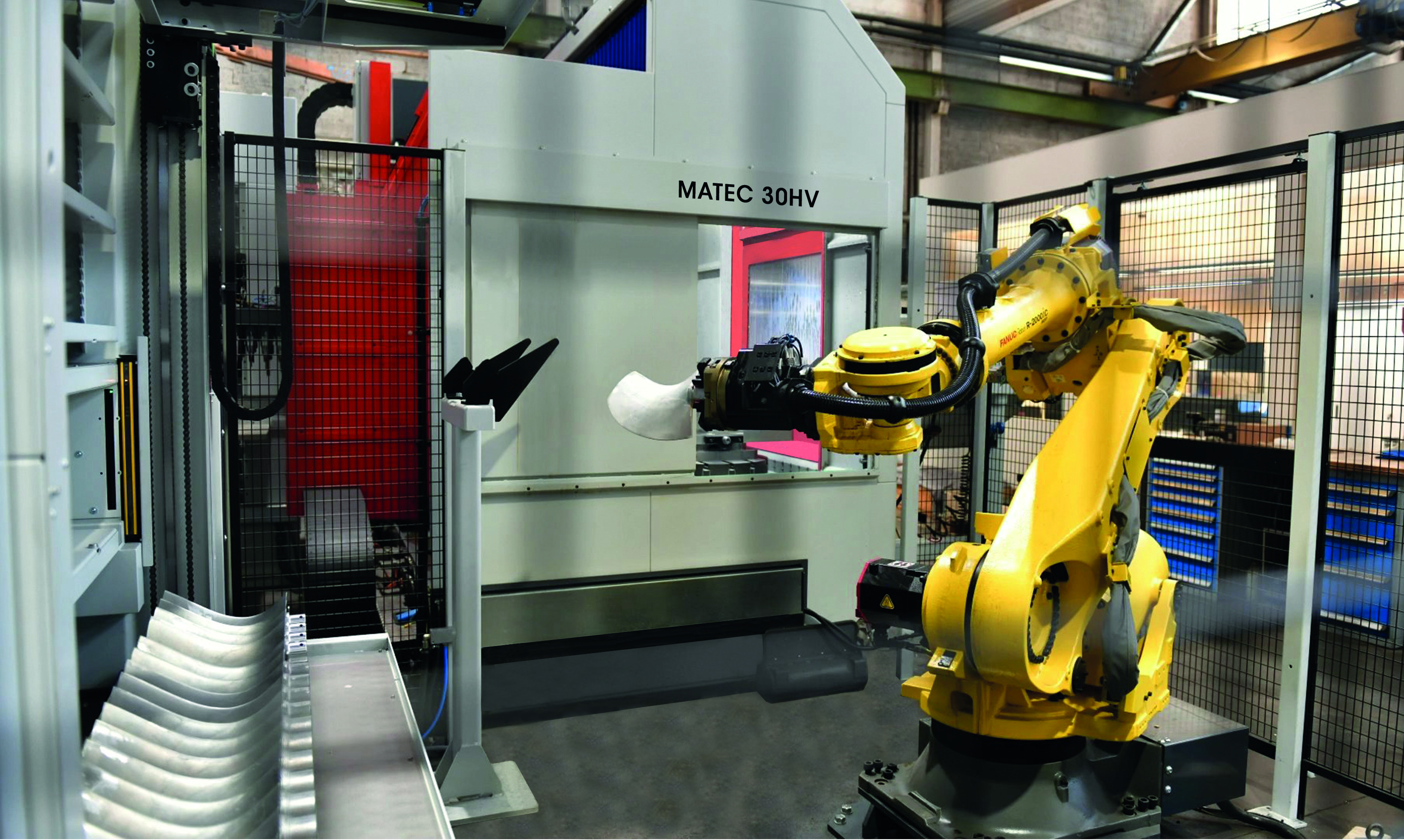

MATEC 30HV | MATEC 50HV

- X-axis: 1.300 to 8.000 mm

- Y-axis: 600 to 1,630 mm

- Z-axis: 800 to 1,850 mm

- Built-in rotary table Ø 630 to 2,200 mm

- 1-axis swivel head (infinitely variable)

- Speeds up to 42,000 1/min

- Motor spindle up to 92 kW

- Torque up to 690 Nm

- Tool capacity 48 or 268 tools with add-on magazine

- Fully enclosed work area; prepared for mist collection

- 6-axis robot, size based on the required payload or workpiece weight

- High rack with workpiece drawers, individually adjustable to the specific workpiece height

- Alignment stations for different workpieces

Customized solution. - 5-axis series production of turbine blades

Our standard series – with intelligent automation

MATEC 30SHV | 30S | 30SD with swivel table

The ideal combination of high-productivity series machines and effi cient automation

MATEC 30SHV

- Swivel table

- Swivel head ± 105°

- X-/Y-/Z-axis 2000/600/800 mm

Multi-sided or end machining on long workpieces with

a length of up to 800 mm

Automation sample: MATEC 30SHV

Plant interlinked in a line with upstream and downstream

process steps.

3-sided machining of profiles. MATEC manufacturing

cell with loading and unloading during machining

operations.

Additional processes: deburring, washing and drying

at the loading station.

Automation

- 6-axis robot

- 2 x drawer-type magazine with six drawers

- Drawers can be loaded externally

- Alignment and positioning station

View or the work areas with the safety partition wall

at the centre of the swivel table open. 6-axis robot in

unloading position.

Two workpieces clamped in each work area. Machining

of both ends by means of swivel head.