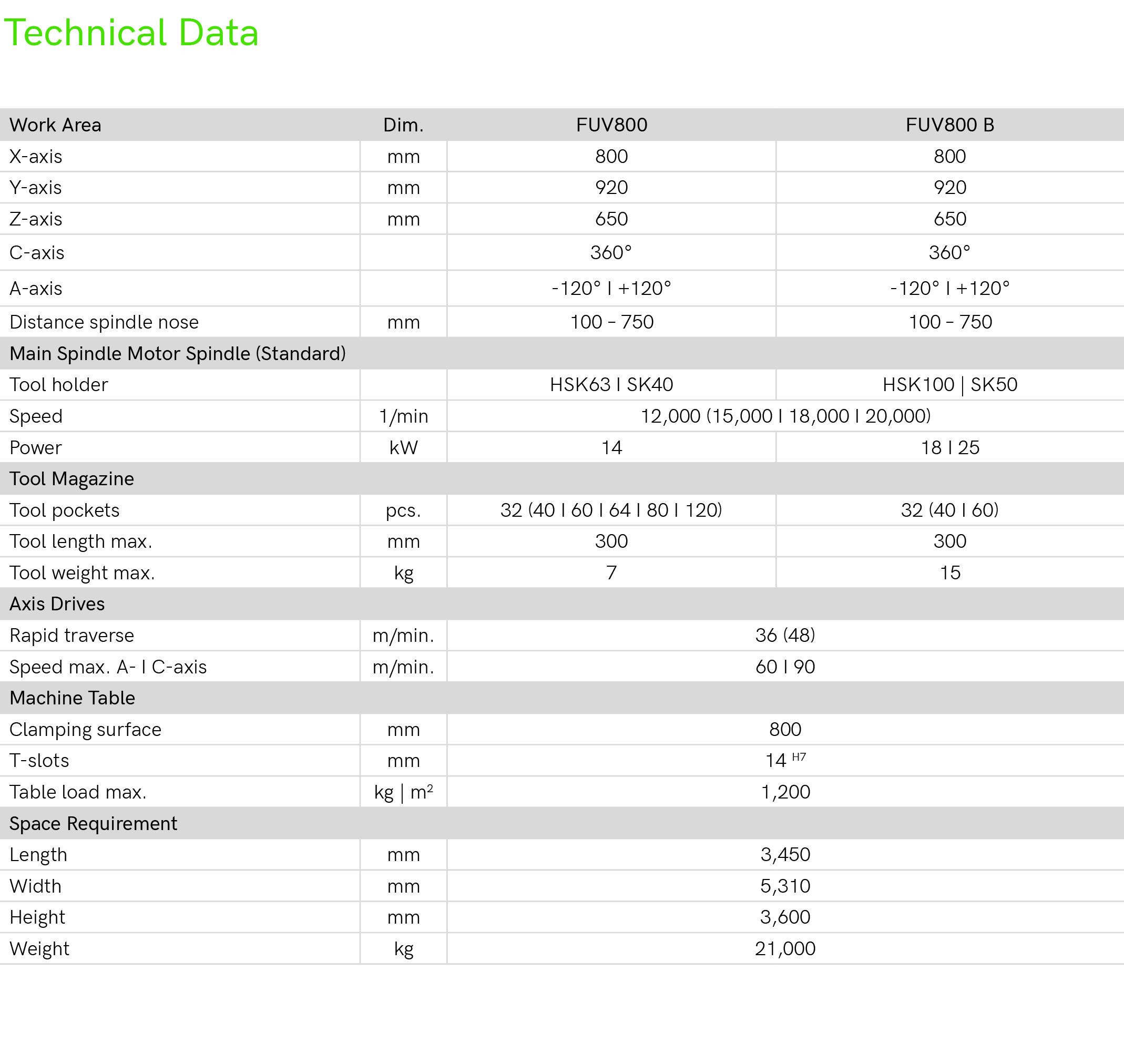

MATEC FUV800 I FUV800 B - 5-Axis Gantry Machining Centre

Performance class HSK63 I HSK100

The model FUV800 I FUV800 B has been designed for

an elaborate production of intricate parts and shapes

in 5 axes. The gantry design provides for a high rigidity

and concentration of accelerated mass resulting in an

excellent dynamic conception.

The machine base consists of tightly ribbed cast.

Prior to mechanical processing, the whole column

structure is being stress-relieved.

The whole structure stands out by its high thermostability

allowing precise simultaneous 5-axis machining

of workpieces.

The swivel bridge incorporated into the side walls

and the perfectly integrated axis rotation points of the

table allow machining of workpieces up to a total

weight of 1,200 kg.

The machine table has a diametre of 800 mm, allowing

to process workpieces with a max. diametre of

900 mm and a height of 550 mm.

The rotation axis allows a full 360° turn. The swivel

axis has a swivel range of +120° I -120°. All axes are

equipped with direct path measuring systems.

Loading of workpieces can be done in a highly efficient

way due to the max. distance of 720 mm between door

edge and centre of the machine table.

The machine can be equipped with max. 120 tools in

HSK63 I SK40 and 60 tools in HSK100 I SK50. The

standard version is equipped with 32 tools each.