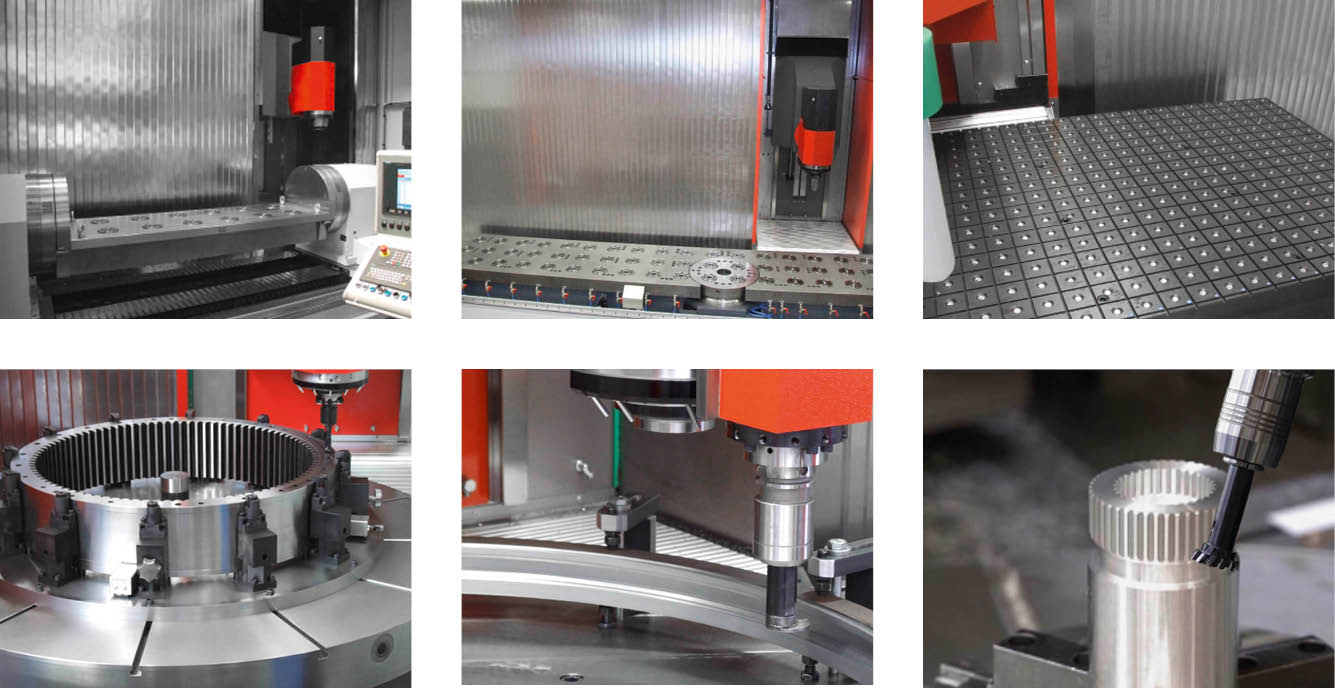

Flexible set-up and clamping systems - Our strength

For both performance classes

Multi-side machining

- Rotary table and counter bearing, positionable via CNC axis

- Quick-change system with rotary feed-through

- Control of hydraulics, pneumatics, electrics and vacuum

- Swivel bridges and fixtures, also for direct clamping of

workpieces in different lengths

Maximum flexibility

- Machine table and CNC rotary table with integrated

zero-point clamping systems. Perfect fixture and

workpiece clamping in different applications - The make of the zero point clamping system and the

arrangement of the clamping elements (grid) are

freely selectable

Clamping systems for large workpieces

- Magnetic or vacuum clamping

- Movable suction unit

- Complete solutions from one source

Mill turn centre: Variants and combinations

- Motor spindle with integrated clamping

- Additional tool holder for heavily interrupted cuts

during turning - One or two rotary tables for pendulum machining

- Rotary tables integrated in the machine table or

free-standing - Rotary tables with direct drive up to 1,000 1/min.

- Faceplates from Ø 630 to 3,000 mm

- Rotary spindles up to 6,000 1/min.

- Option "grinding" possible

- Production of various gearings

- Gear hobbing, straight or helical, including shifting

- Skiving, internal and external

- Gear cutting, internal and external