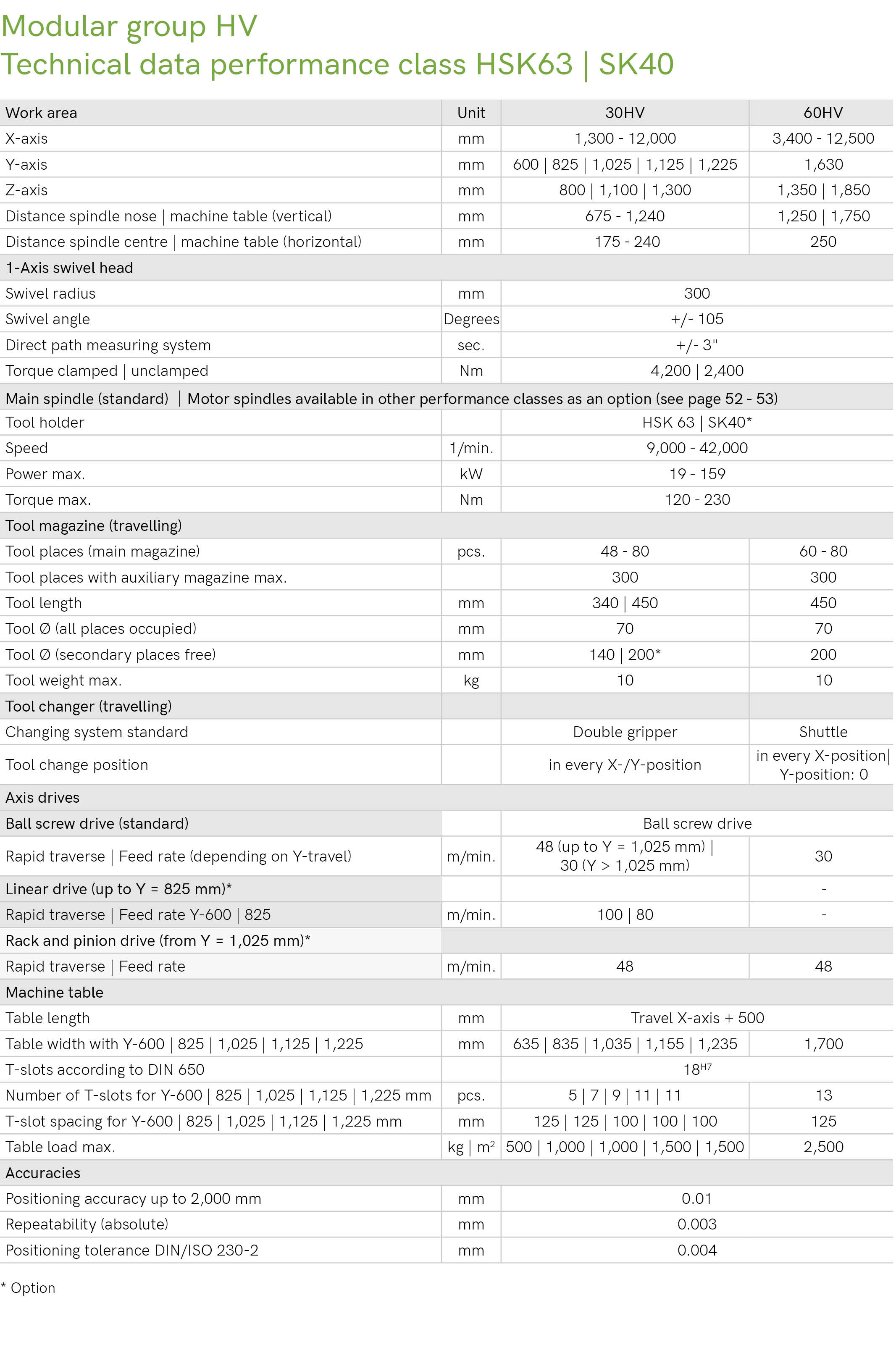

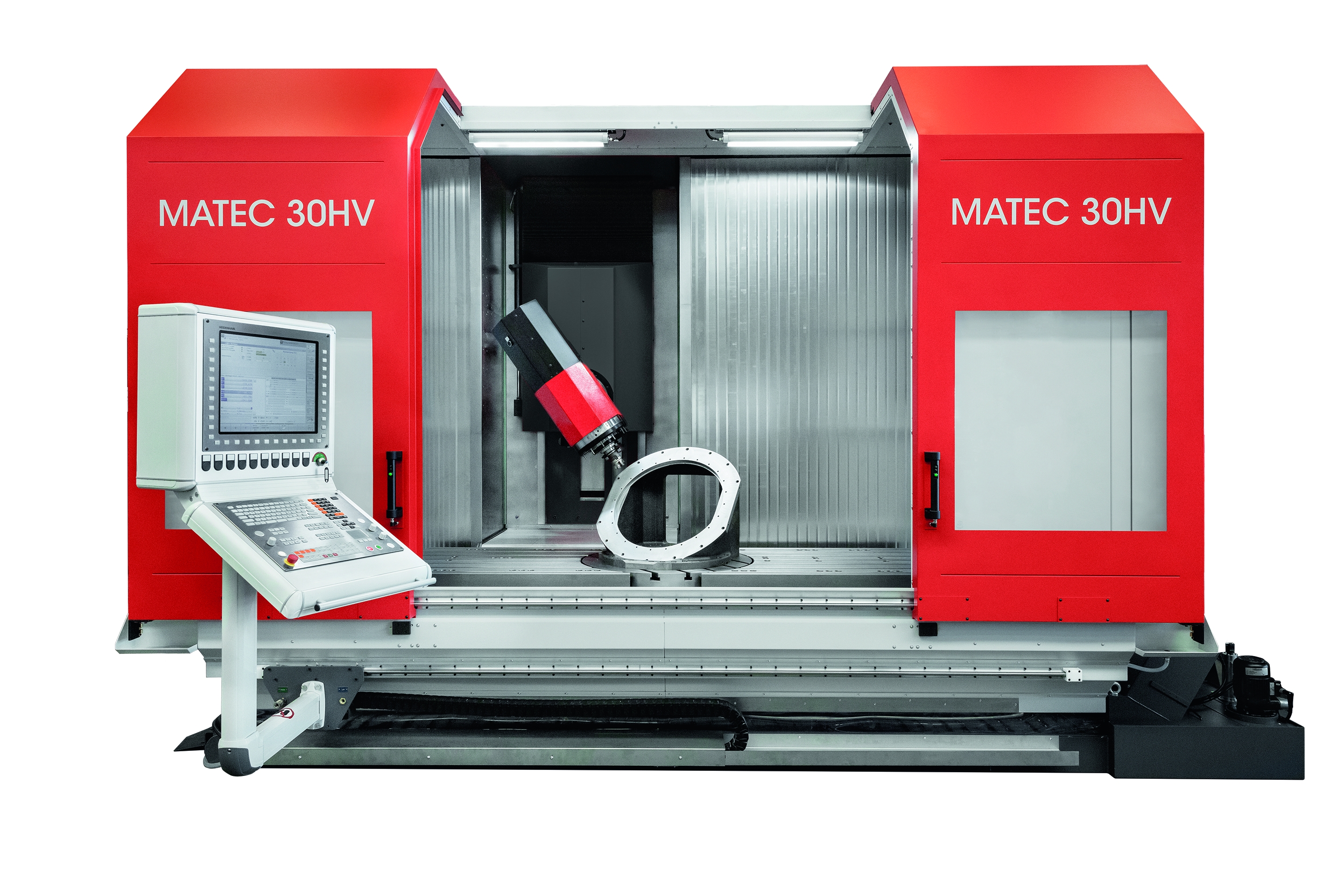

MATEC 30HV I 60HV - Standard equipment – machines and options

Performance class HSK63 | SK40

Standard equipment

- 1-Axis CNC swivel head, infinitely variable

- CNC control Heidenhain TNC 640

- Speed: 9,000 1/min

- Motor spindle: Drive power max. 19 kW

- Torque: max. 120 Nm

- Tool holder HSK63

- 30HV tool change with double gripper,

48 tool places - 60HV tool change with shuttle,

60 tool placesAxis drives with ball screw drive - Roller linear guides in all axes

- Direct path measuring systems

- Standard machine table with T-slots

- Full work area enclosure with roof

- Chip conveyor

- Coolant unit

Options for the basic machine

Swivel head

- Dynamic CNC swivel head with direct drive

Motor spindle

- Higher power motor spindle

― Speed range: 12,000 to 42,000 1/min

― Power: up to max. 159 kW

― Torque: up to max. 230 Nm - Tool holder SK40

Drive system

- X-axis with linear drive

- X-axis with rack and pinion drive

Options independent of the performance class

Machine table assembly group

- Customised machine table assembly group

- Integrated or top-mounted rotary tables, position freely selectable

- CNC rotary tables for positioning and turning

- Other table heights

- Adaptation of T-slots to customer's existing fixtures and clamping systems

- Zero-point clamping systems according to customer requirements

- Swivelling machine tables according to the customer's requirement profile.

- Tool changing system with shuttle from Y-axis 825 mm and Z-axis 1,100 mm

- Partition wall for pendulum machining, fixed or variable position

- Automatic work area doors

Tool magazines / capacity extensions

- Additional magazines, pick-up magazines

Automation and special equipment

- Mill turn with automatic balancing in the machine

- Sawing units, multi-spindle and angle heads

- Deep hole drilling

- Workpiece machining from bar (bar feeder)

- Loading automation, pallet change

- Friction stir welding (FSW)